In a manufacturing industry, the inventory refers to the finished goods, raw materials and other processes/unfinished items kept in the store. These are valuable goods that need to be handled with care for an uninterrupted production process. A manufacturing inventory control is a process with several techniques involved with respect to the nature of business process.

For example : Let’s consider a chocolate manufacturing company. The inventory will be loaded with raw materials like cocoa beans, sugar, flour etc, then containers of liquid chocolates stored for processing and the final chocolate bars packed ready for the deliveries.

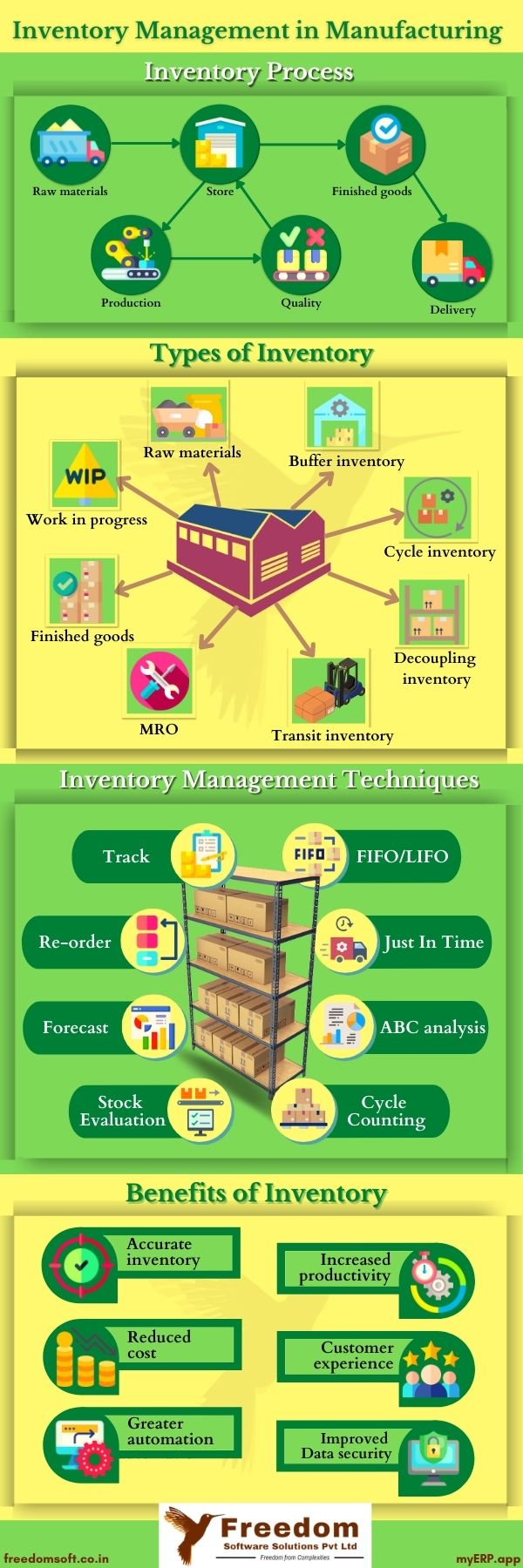

Inventory Process :

There are many stages of manufacturing inventory control that a company should monitor and keep track of each and every information to ensure uninterrupted production in the shop floor. From the purchasing of raw materials till the goods delivery there are a number of tasks which are entered in an efficient inventory management ERP software for accurate data. Let us briefly discuss the major inventory processes.

- Purchase : The purchase department makes the required purchase of raw material after negotiations with several suppliers. This is brought and stored in the company’s inventory and every entry with respect to resources’ size, quantity and location has been entered in the ERP.

- Store : This a physical space in any manufacturing industry where all the materials/goods are stored in the racks and shelves that are closely monitored by the store keeper. His job is to keep record for every movement in and out of the store.

- Production : Once the materials have been purchased, next the production team makes requests for required resources for the assigned project. Now again the materials are moved from store to shop floor.

- Quality : After all the processes the finished goods are finally ready to be packed. But before packing it goes for a quality check to ensure all the necessary standards have been met and defect less. Now the quality products have been manufactured and moved to stores for further packing.

- Delivery : The final goods are being packed and kept a record for each batch with an accurate number of items per batch. The products are being delivered to the allocated locations.

Types of Inventory :

The processed items that we said in the chocolate manufacturing example are one type. But in reality there are so many different types of inventories, depending upon the various industries and products. Listed down are the major types of inventories.

Raw materials :

Raw materials are the materials needed for the production of a product. The RM can be of two types again. In manufacturing industries, for example a fabrication industry will have steel bars as raw materials that are purchased from their suppliers and other RM like by products. By products are nothing but a part of the item that requires to form the final product. Here instead of buying it as raw materials the manufacturers also buy it as a product incase there are no machineries available in the shop floor to produce it from scratch.

Work In Progress :

As the name implies, these are items that are processed but not assigned as the final product. In the above said example, a cocoa bean is extracted, roasted and boiled to attain the liquid chocolate but still kept in the store for further processing. The Work In Progress materials are majorly used in manufacturing industries only.

Finished Goods :

The RM, after going through all the process and quality checks it is now approved as the finished goods ready for sale. In the example above, the liquid chocolate is cooled and formed into desired shapes as a bar, checked for any defects and packed in different sizes and weights. This is now considered as the FG and prepared to get delivered.

These three such as Raw materials (RM), Work In Progress (WIP) and Finished Goods (FG) are the major types of inventories in any manufacturing and other types are for specific purposes listed below.

MRO Inventory :

MRO stands for Maintenance Repairing and Operating supplies. These are not accounted as inventory but some supplies and tools that should be mandatory for efficient functioning of the machines. There is a list and minimum quantity of these inventories to be maintained on a regular basis. Examples for MRO are lubricants, coolants, nuts, bolts, screws etc.

Buffer Inventory :

The manufacturing supplies and demand are a constant fluctuating thing where no one can predict the sales. In situations like this there is a more chance to get out of stock. This obviously creates a bad impression among our customers. To prevent such issues and be well prepared to face the changing market, the buffer inventory is used. This is nothing but the additional stock that saves you from critical times like transport or labor strikes.

Cycle Inventory :

Cycle inventories are materials that are always ordered in huge numbers and on a regular basis. These inventories will have day to day usage in each and every process throughout the production.

Decoupling Inventory :

Decoupling inventory comes into picture when any of the sequential processes gets defected due to sudden cause and this in turn affects its next process in the queue finally resulting in the delay of production. To prevent such issues the manufacturers keep an additional inventory that could help ensure smooth functions of the process.

Transit Inventory :

Transit inventory are the inventories like raw materials or the finished goods that are being relocated or moving from one location to another.

Inventory Management Techniques :

1.Track : All the movements of inventory materials in and out of the premises during purchase and delivery should be tracked accurately. This allows you to maintain the inventory level once we know the exact real time data.

2.Reorder : Once we have a better view on the current stock levels, it enables you to reorder instantly whenever there is a low number or out of stock is about to happen.

3.Forecast : Forecasting can be done by analyzing the previous data and predicting the facts of demand. The market trends are always on a change and to meet the ever changing demands of customers we have to be ahead of competitors to handle critical situations effectively.

4.Stock Evaluation : Stock evaluation is done for various purposes like to cross check any manual errors such as miscalculation. Also studying the stock movements and numbers during different periods helps us to determine a reorder level in future. This helps in forecasting as well.

5.FIFO/LIFO : First In First Out and Last In Last Out are the two different methods used for the inventory movement. This method is set up for each product/item in store after analyzing which is the best practice. It is greatly helpful in efficient utilization of raw materials and goods.

6.Just In Time (JIT) : Just in time as the name implies the deliveries are done on time reducing lead times. This method needs high knowledge on logistics insights like weather, geographic location and political events. The purpose is to avoid stockpiling of products for future use and promote quick inventory turnover.

7.ABC Analysis : This method categorizes inventory into three types, a)goods with low availability but high profits, b)goods with moderate availability and value, c)goods with low value with high availability. This study enables you to maintain healthy stock levels that provide flexibility incase of unexpected demand fluctuations.

8.Cycle Counting : Cycle counting is a method where the manual counts are done as groups of stock materials hence saving time. This is repeated until all stock quantities are recorded by the end of the year.

Benefits of Inventory Management Systems :

Accurate inventory : Since inventory management software has every detail of item movements that happen during various stages of production, the inventory level is maintained accurately. This is a great benefit to the company in providing on time delivery.

Reduced cost : We might have heard a saying that inventory is another form of money sitting in the stores. If not utilized effectively the manufacturers can face a huge loss. But using inventory management this can be completely eliminated and resulting in cost savings.

Greater automation : Using ERP for inventory greatly increases automation in terms of stock evaluation, reordering materials on time, maintaining correct inventory levels and thus reducing labor hours.

Increased productivity : Since inventory software reduces errors, ensures uninterrupted supply of materials, the productivity is enhanced as there is more time for laborers to focus on with many other issues and tasks.

Customer experience : By delivering products on time to the customers, you get valuable feedback and help to sustain loyal customers gaining trust. This adds a solid relationship between consumers thus improving brand value and recognition.

Improved data security : As the system restricts access to the users on company’s confidential data on inventory, this prevents potential costs of data breach.

Conclusion : Everything is modernized and technology has developed to great extent easing the life of many business owners. It is very essential that we adapt to those systems and get benefitted gradually. For complex businesses like manufacturing and a more complicated process like inventory, the ERP software is the all in one solution in business performance improvement.